Weaving:

The process of producing a fabric by interlacing warp and weft threads is known as weaving. The machine used for weaving is known as weaving machine or loom. Weaving is an art that has been practiced for thousands of years. The earliest application of weaving dates back to the Egyptian civilization. Over the years, both the process as well as the machine has undergone phenomenal changes. As of today, there is a wide range of looms being used, right from the simplest hand loom to the most sophisticated loom.

|

Classification of Weaving Machines:

Weaving machines are classified according to their filling insertion mechanism. The classification is as follows:

Weaving machines are classified according to their filling insertion mechanism. The classification is as follows:

1. Shuttle

2. Shuttle-less

In shuttle weaving, a shuttle that traverses back and forth across the loom width, inserts the filling. Shuttles can be made of wood or plastic. Filling yarn is wound on the quill and the quill is placed in the shuttle. As the shuttle move across the loom, the filling yarn is unwound from the pirn and lay in the shed.

2. Shuttle-less

- Projectile

- Rapier

- Air-Jet

- Water-Jet

In shuttle weaving, a shuttle that traverses back and forth across the loom width, inserts the filling. Shuttles can be made of wood or plastic. Filling yarn is wound on the quill and the quill is placed in the shuttle. As the shuttle move across the loom, the filling yarn is unwound from the pirn and lay in the shed.

|

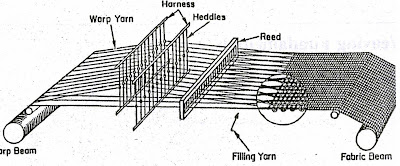

| Fig: Basic Weaving Mechanism |

Projectile Weaving

Projectile weaving machines use a projectile equipped with a gripper to insert the filling yarn across the machine. The gripper projectile draws the filling yarn into the shed. The Projectile glides through the shed in a rake- shaped guide. Braked in the receiving unit, the Projectile is then conveyed to its original position by a transport device installed under the shed.

Projectile weaving machines use a projectile equipped with a gripper to insert the filling yarn across the machine. The gripper projectile draws the filling yarn into the shed. The Projectile glides through the shed in a rake- shaped guide. Braked in the receiving unit, the Projectile is then conveyed to its original position by a transport device installed under the shed.

|

Fig: Projectile Weaving |

Rapier Weaving

In Rapier weaving, a flexible or rigid solid element, called rapier, is used to insert the filling yarn across the shed. The rapier head picks up the filling yarn and carries it through the shed. After reaching the destination, the rapier head returns empty to pick up the next filling yarn, which completes the cycle. A rapier performs a reciprocating motion.

In Rapier weaving, a flexible or rigid solid element, called rapier, is used to insert the filling yarn across the shed. The rapier head picks up the filling yarn and carries it through the shed. After reaching the destination, the rapier head returns empty to pick up the next filling yarn, which completes the cycle. A rapier performs a reciprocating motion.

|

Picture: Weft insertion by rapier |

Rapier weaving machines can be of two types:

1. Single Rapier Machines: A single, rigid rapier is used in these machines. The rigid rapier is a metal or composite bar usually with a circular cross section. The rapier enters the shed from one side, picks up the tip of the filling yarn on the other side and passes it across the loom width while retracting. Therefore, a single rapier carries the yarn in one way only and half of the rapier movement is wasted. Also there is no yarn transfer since there is only one rapier. The single rapier’s length is equal to the width of the loom.

2. Double Rapier Machines: Two rapiers are used in these machines: one rapier, called the giver, takes the filling yarn from the yarn accumulator on one side of the loom, brings it to the center of the machine and transfers it to the second rapier which is called the taker. The taker retards and brings the filling yarn to the other side. Similar to the single rapier machines, only half of the rapier movements are used for filling insertion.

Air-Jet Weaving

The air jet weaving machines are the weaving machines with the highest weft insertion performance and are considered as the most productive in the manufacturing of light to medium weight fabrics, preferably made of cotton and certain man-made fibers (sheets, shirting fabrics, linings, taffetas and satins in staple yarns of man-made fibers); it has anyway to be pointed out that technically positive results are obtained at present also with heavy weight fabrics (denims) and that some manufacturers produce also machine models for terry production.

|

Fig: Air-Jet Weaving |

These machines are the ideal solution for those who want to produce bulk quantities of customized fabric styles. The weaving widths range generally from 190 to 400 cm. As regards the multicolor weft carrier, up to 8 different wefts can be fed. It has however to be considered that the air jet weaving machines require a high energy consumption to prepare the compressed air and that this consumption rises definitely with increasing loom width and running speed. The reduction in the energy consumption is in fact one of the main concerns of the manufacturers, and builds for the user an important selection criterion.

Water-Jet Weaving

A water-jet weaving machine inserts the filling yarn by highly pressurized water. The relative velocity between the filling yarn and the water jet provides the attractive force. If there is no velocity difference, then there would be no tension on the yarn results in curling and snarling of the yarn. Water-jet weaving machine can only be used for hydrophobic fibers.

A water-jet weaving machine inserts the filling yarn by highly pressurized water. The relative velocity between the filling yarn and the water jet provides the attractive force. If there is no velocity difference, then there would be no tension on the yarn results in curling and snarling of the yarn. Water-jet weaving machine can only be used for hydrophobic fibers.

|

Fig: Water-Jet Weaving |

No comments:

Post a Comment